For starters, Toolox® had to have excellent machinability and dimensional stability in machining operations. We also combined the machinability with high hardness by prehardening the steel to avoid the need for additional heat treatment after machining. This was made possible by a low carbon content, a suitable mix of alloying elements and a carefully controlled quenching and tempering process.

The machinability and prehardened properties savetime and make your production much more cost effective compared to standard steels. When your customers say they want it fast, you can deliver without compromising on quality and performance.

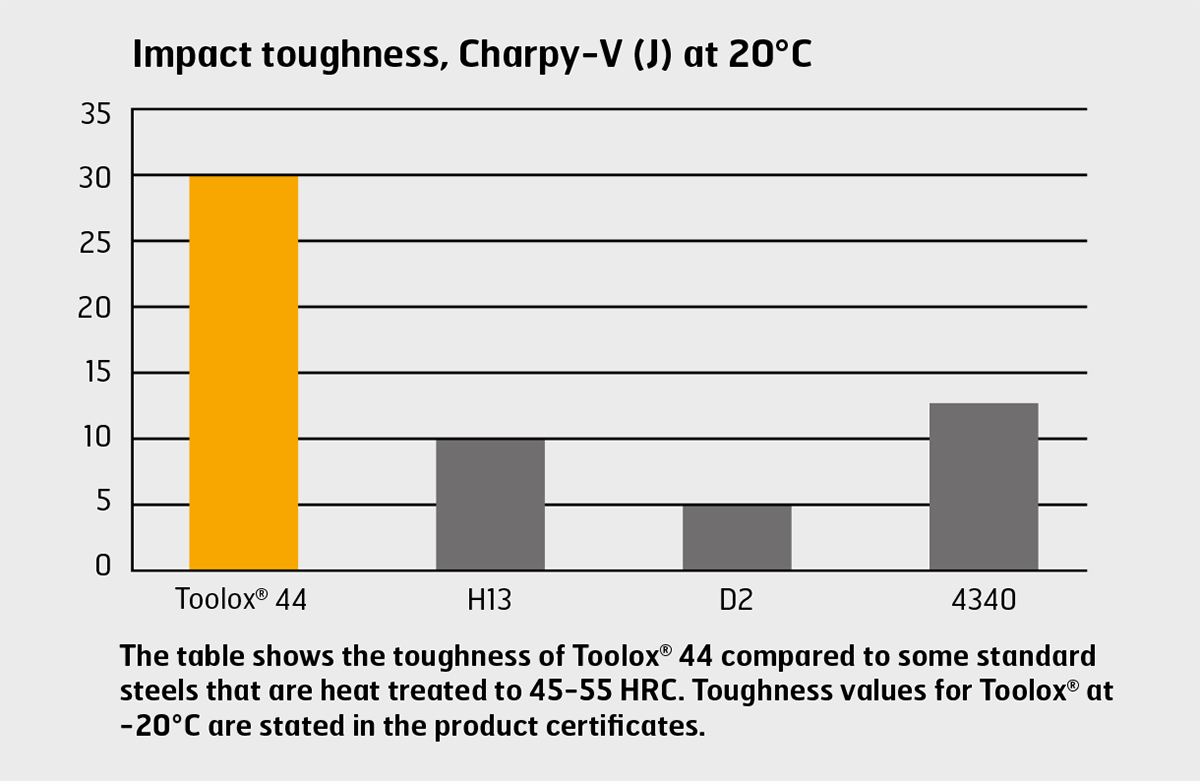

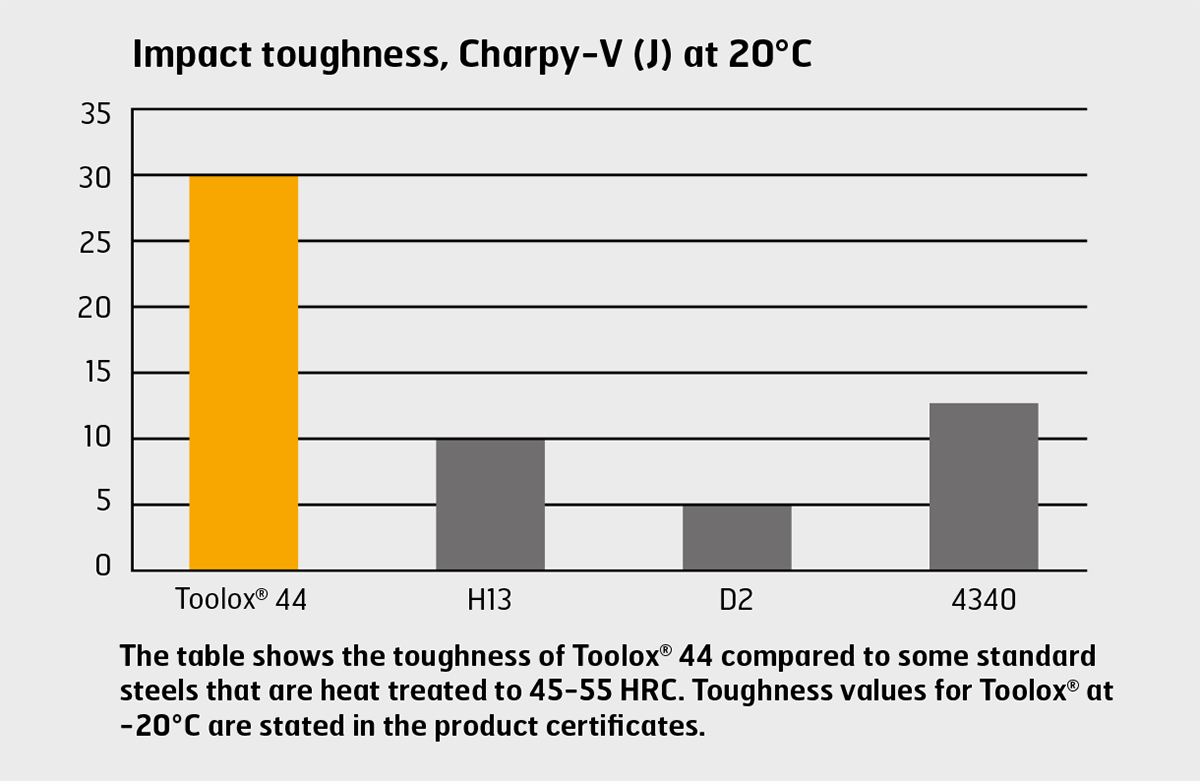

The chemical composition and the production

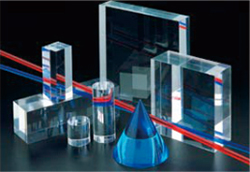

process also gives Toolox® its high impact toughness and crack resistance, properties that ensure flawless performance in the end user's equipment. Fatigue resistance is another vital property in Toolox® since it gives long service life for the components. This was secured by the steel’s superior cleanliness,making it exceptionally suitable for surface engineering, polishing and texturing.

The hardest pre-hardened tool steel in the world

Why should we use Toolox® ?

The machinability and prehardened properties savetime and make your production much more cost effective compared to standard steels. When your customers say they want it fast, you can deliver without compromising on quality and performance.

The chemical composition and the production

process also gives Toolox® its high impact toughness and crack resistance, properties that ensure flawless performance in the end user's equipment. Fatigue resistance is another vital property in Toolox® since it gives long service life for the components. This was secured by the steel’s superior cleanliness,making it exceptionally suitable for surface engineering, polishing and texturing.

The hardest pre-hardened tool steel in the world

| Toolox®44 | Toolox®40 | Toolox®33 | ||||

| Hardness | 410-475 HB | 360-420 HB | 275-325 HB | |||

| Yield strength at 20℃ | 1300 Mpa | 1150 | 850 | |||

| Tensile strength at 20℃ | 1450 MPa | 1260 | 980 | |||

| Elongation | 8 | 10 | ||||

| Impact energy | 30 J | 38 J | 100 J | |||

| Thermal conductivity 20℃ | 28 | 35 | ||||

| 200℃ | 32 | 35 | ||||

| 400℃ | 29 | 30 | ||||

| 600℃ | 21 | 23 | ||||

| Thermal expansion 20℃ | 13.5 | 13.1 | 13.1 | |||

| 200℃ | 13.5 | 13.1 | 13.1 | |||

| 400℃ | 13.5 | |||||

Why should we use Toolox® ?

| Hardness and toughness | Toolox® is a prehardened engineering and tool steel that is hard to the core and tough at the same time. |

| Fatigue resistance | Toolox® is a prehardened engineering and tool steel that is hard to the core and tough at the same time. |

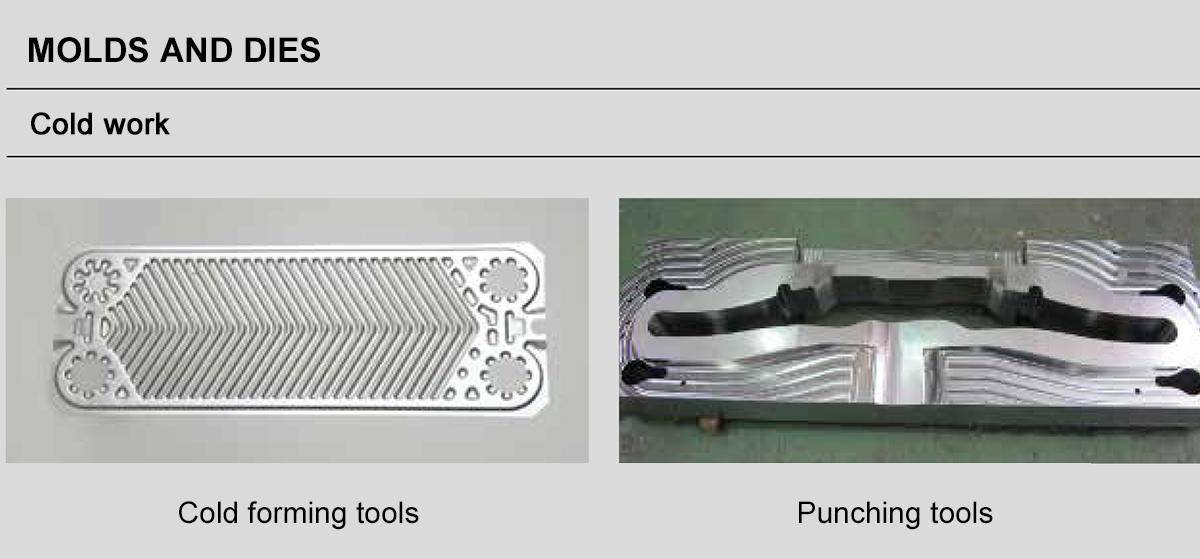

| Machinability | The homogenous structure and low carbide content give Toolox® excellent machinability with fast cutting speeds and long insert life. |

| Surface treatment | Toolox® is well suited for all kinds of surface treatments that increase the material’s hardness and fatigue resistance even further. |

| Heat resistance | Toolox® can work continuously at temperatures as high as 590°C and still keep its original hardness when cooled. |

| Welding and cutting | The low level of alloys in the Toolox® grades makes for predictable welding and thermal cutting with all conventional methods |

| Production efficiency | The faster the better, and Toolox® speeds up production with days and even weeks thanks to its prehardened properties. |

| Longer lifetime | The proof is in the real-life performance, and Toolox® has demonstrated its longevity and reliability in multiple challenging applications. |

| Guarantees | Every plate and round bar of Toolox® is tested to ensure the material’s consistency. The dimensions and properties you expect is what you get, every time. |